Our Commitment

Committing to sustainability transcends from the very top of organization into one of main business focusses for the future of the Group and the industry. Using the UN Sustainability goals to address continuous environmental improvement and partnerships in community means that we are committed, in every step of our processes, to a cleaner future. For Cavagna Group, considering the Energy Transition is no longer a choice, it is a priority.

SUSTAINABILITY

INNOVATION

ENERGY TRANSITION

Sustainability

As an International Group, we are aware that the importance of sustainability and its definition varies somewhat depending on the area. This is not due to the lack of importance of sustainability but in relation to the priorities of that specific market in regards to economy, health, different local targets and the speed of the development status. Committing to sustainability transcends from the very top of our organization into one of our main business focusses for the future of the Group and the industry.

Using the UN Sustainability goals to address our continuous environmental improvement and partnerships in our community means that we are committed, in every step of our processes, to a cleaner future. For us, considering the Energy Transition is no longer a choice, it is our priority.

Green Mission

Knowing that the gas molecule play a part in the future of energy, we at Cavagna Group, are conscious about our contribution to the environment and future of our planet. We aim to transcend our sustainability actions from our company into the entire supply chain.

Green Vision

Our products will be a key component in a sustainable supply chain in regards to treatment, transportation, storage and usage. Alongside, promoting a digital transformation to further assist in a greener world.

In recent years, Cavagna Group has been increasingly working on consolidating its commitment to the sustainable energy transition and digital transformation of the sectors it operates in. In fact, the Group aims to be there wherever gas fuels progress and life and brings innovative solutions to the twin transition.

Besides focusing on the development of IoT solutions and digitally controlled technologies, the Group has undertaken a path to offset its pollutant emissions.

This commitment translates into:

- Optimisation and certification of production processes to minimise negative effects on the environment and improve energy use;

- Active participation in environmental protection and social development projects carried out in different parts of the world.

If you would like to find out about all the projects we are involved in, visit the Climate Page (u2y.io).

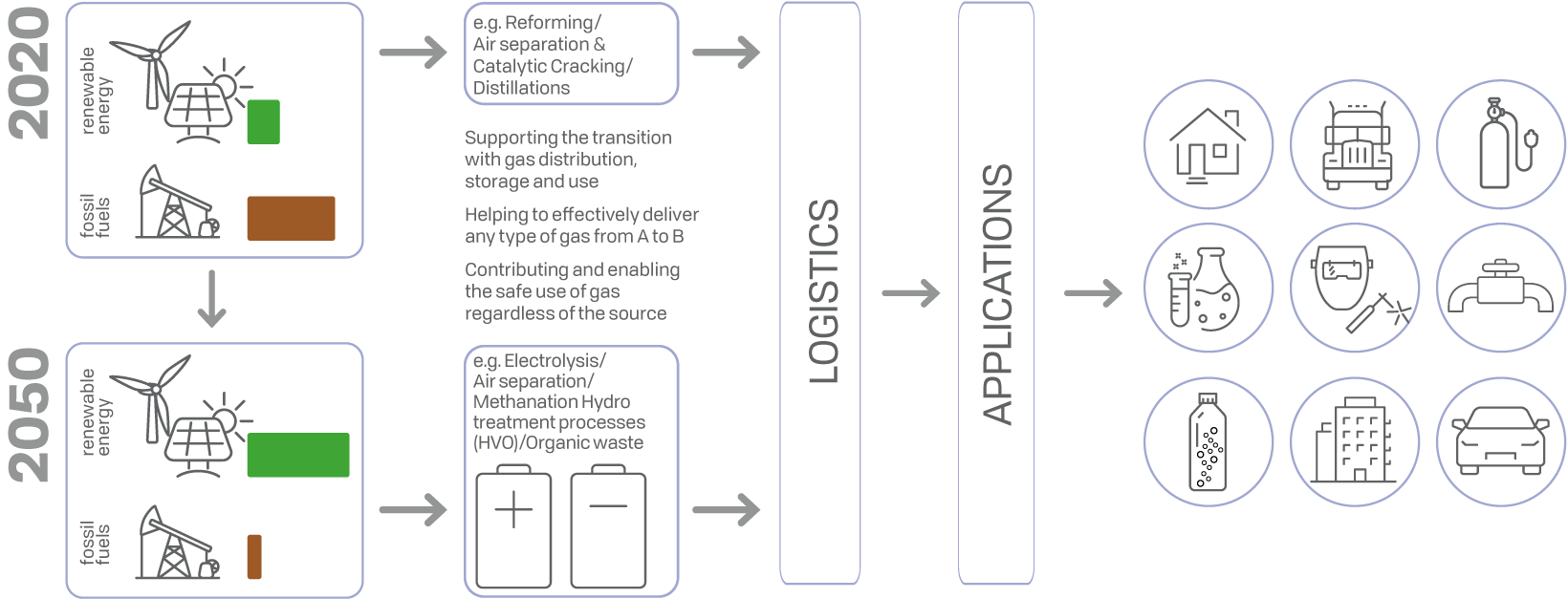

Cavagna Group is an enabler in different gas molecule supply chains, facilitating a sustainable process at every step, regardless of the source of fuel.

As we move into bio and renewable, Cavagna Group gas committed to providing the same quality and consistency of safety and reliability in their products for every step of the process. From treatment/production, transportation, storage and use.

LEARN MORE

It is important to note that Cavagna Group is part of the cluster of skills in mechanical technologies connected to multiple gas supply chains and intended for the management of pressurized gases in distribution, storage and uses. Cavagna Group and other gas equipment manufacturers are relevant to manage the treatment, transportation, storage and safe usage. Regardless of the type of gas, equipment is necessary and essential.

Meaning that all of these processes still require the expertise in regards to safety, efficiency, reliability and accessibility that the longstanding gas industry players have accumulated over the last 100 years. Repco is Cavagna Group’s newest acquisition, putting the Group in the upstream supply chain and the increase in requests for biogas plant projects has become evident in recent times due to energy trends.

Specifically, Repco specializes in the conversion of electricity production plants from Coal to lower emission solutions with Gas Stations. Looking at Coal to Methane and turbines with methane hydrogen mix, always with a low emission perspective. Cavagna Group has a plan and a vision with all of the above in mind for the future, with the mission that gas will and has a part in the Energy Transition.

In addition to the use of renewable energy sources to minimize emissions of CO2 and other climatealtering gases into the atmosphere, the Group has been promoting all alternative fuels for years as the best choice of alternative energy, both for public transport, heavy traffic, passenger cars and marine applications. Keeping in mind the UN goals and other set initiatives by government bodies.

In order to implement effective and active action focused on environmental protection, besides conducting business in total compliance with both Italian and Community regulations on the environment, the Cavagna Group has launched a series of actions designed to prevent, manage and reduce the environmental impact that is both directly and indirectly related to the activities performed. The environmental policies implemented by the company are regularly performed to achieve ongoing improvements in the results obtained in the framework of environmental protection, in order to exploit the latest technology and good manufacturing practices available. In compliance with International ISO 14001 standards.

The Group has always considered its environmental commitment as one of the key principles of the company, seeking excellence

in the quality of its products, always making sure of the environmental impacts associated with them.

KEY PILLARS OF SUSTAINABILITY

- Sustainable development and responsible transition

- Family company values in line with the Energy transition

- Position the gas molecule as an important player in the field

- Innovation Encourages Sustainability

- Economic, Social and Environmental pillars of sustainable development are all linked to one another

- Be sensitive to different definitions of sustainability for different global markets

Concrete action for our Commitment

To reduce its ecological footprint, the Cavagna Group has implemented a series of environmental policies designed to reduce direct impact. The following is a brief description of the planned strategies, grouped by field of intervention.

OUR COMMITMENT TO THE ENVIRONMENT

The Cavagna Group has always considered its environmental commitment as one of the core principles of the company, seeking product quality excellence and safety while cutting down to a minimum the related environmental impact.

Hence, in order to implement effective and active action focused on environmental protection, besides conducting business in total compliance with both Italian and Community regulations on the environment, the Cavagna Group has launched a series of actions designed to prevent, manage and reduce the environmental impact that is both directly and indirectly related to the activities performed.

The environmental policies implemented by the company are regularly implemented to achieve ongoing improvements in the results obtained in the framework of environmental protection, in order to exploit the latest technologies and good manufacturing practices available.

Lastly, Cavagna Group’s Environment Management System is certified in compliance with the international standard ISO 14001.

POLICY TO MINIMIZE ENVIRONMENTAL IMPACT

To reduce its ecological footprint, the Cavagna Group has implemented a series of environmental policies designed to reduce direct impact. The following is a brief description of the planned strategies, grouped by field of intervention.

Using renewable and sustainable energy sources

The Cavagna Group has long made use of renewable energy sources to minimise the emission of CO2 and other gases that affect the climate in order to prevent climate changes, which are unanimously deemed as the most crucial global environmental challenges, and to cut down the release of pollutants into the atmosphere.

Photovoltaic plant

In 2007 a photovoltaic generator including 375 high efficiency monocrystalline silicon modules with peak wattage of 48.75 kW was initially installed on 440 m2 roof that covers the industrial facility.

Said photovoltaic plant was extensively reinforced in 2010, increasing peak wattage by almost ten-fold (445,44 kWp), covering the industrial facility’s roof surface of 3,080 m2 with 1,856 high efficiency monocrystalline silicon modules.

The power yearly generated by the plant is 441,463 kWh, which is little more than 25% of the mean yearly consumption of the facility.

In terms of environmental protection, production of such a quantity of energy from a renewable source has avoided about 345 tons of CO2 from being yearly released into the atmosphere, which is the amount of CO2 absorbed by 6,500 m2 of woodland.

Renewable energy plant powered by biomasses

The facility has a cogeneration plant for power generation from a renewable source (raw vegetal oil), with nominal power 420 kW (electric) and 380 kW (thermal). It produces about 3.15 GWh a year.

Thermal energy recovery

From the cogeneration plant motor cooling water and from exhaust fumes, heat is recovered and used as a source of thermal energy: water that cools the cogenerator motor is channelled to preheat water used by washing machine to rinse items.

Moreover, in winter, it is also used to warm the water that runs through boilers employed for internal heating.

High efficiency lighting

All the lighting systems of the facility are fitted with energy saving dimmers. The use of LED lamps is also being assessed to cut down power consumption.

Sustainable mobility

The ecosustainable transport solution implemented by the Cavagna Group includes 30-35 company vehicles that are rented to employees. These vehicles are regularly replaced and serviced (the mean duration of a contract is 48 months).

The corporate car policy envisages the possibility of only choosing from models manufactured by Italian firms (with one exception), and envisages measures to cut down CO2 emissions (e.g. engine capacity limit of the cars).

To reduce work-related travel, the company also encourages the use of the latest tools of virtual communication. Lastly, for the same purpose, a canteen and a crèche have been opened in the premises for employees. Recently, Our company introduced the figure of Mobility Manager, who will have the task of managing home-work trip.

Virtuous Water Circulation

The installation of a vacuum evaporator and of an osmosis plant for washing machine water enables separation of the oily part of water, with the following results: prior to installation about 50,000 litres of oil mixed with water were disposed of every year; now about 10,000 litres of only oil are disposed of every year. The water recovered by the evaporator is used to top up the water level of tanks. The company has an authorised water well, used for the climatic refreshment of the rooms in the department.

Other policies for sustainable use of resources

Besides the above, the Cavagna Group also adopts other strategies and policies to cut down the use of resources, including: packaging reduction policy; reutilisation and recycling of packaging sent by suppliers; creation of water emulsion circuit and recovery of wood shavings in order to recycle water free of bacteria for processing. Particularly, work implemented to ensure that water is not contaminated by bacteria has allowed to cut down the number of oil tanks used yearly for processing from 18 to 7 (1,000 litres each).