Continuous innovation in products and production stages

The use of top-notch technology has always been part of the Cavagna Group’s strategy to ensure product quality and reliability. This entails continuous research and assessment to seek out cutting-edge processes which can be incorporated into the workflow to bring about substantial organizational improvements.

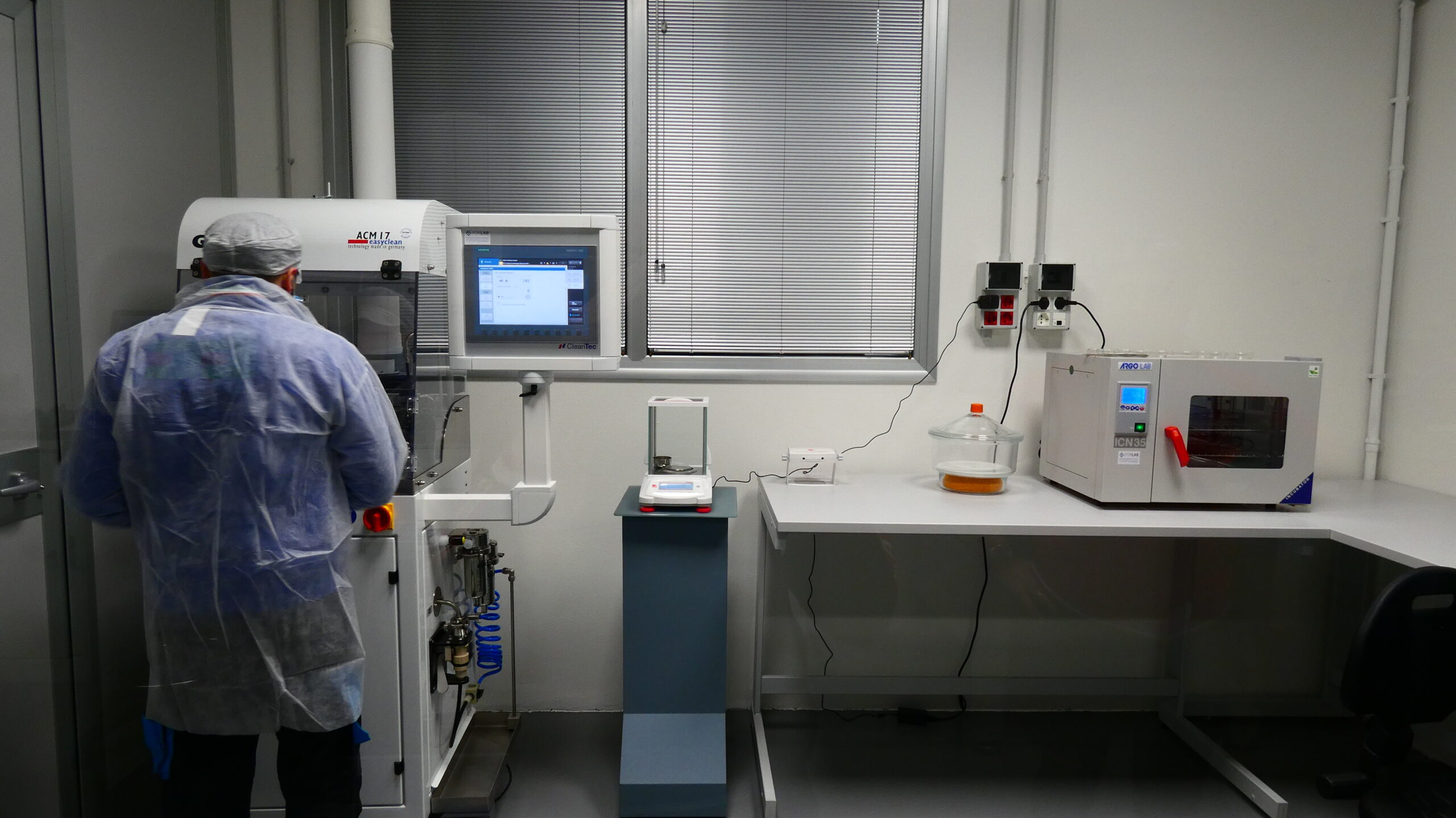

The latest addition to the Group’s laboratories is a new cleaning booth. This booth performs detailed analyses of component cleanliness, which is vital to ensure their efficiency and attain the various necessary certifications.

The medical and industrial oxygen components the Group manufactures are among the most intricate, requiring continuous vigilance. In the past, samples were dispatched to certified external partners for analysis, who subsequently returned the test results.

By carrying out this process on-site, we can save a lot of time and perform more frequent and even more thorough checks than the many already enforced. With goods no longer needing to be moved, there are substantial benefits both for logistics and transportation too.

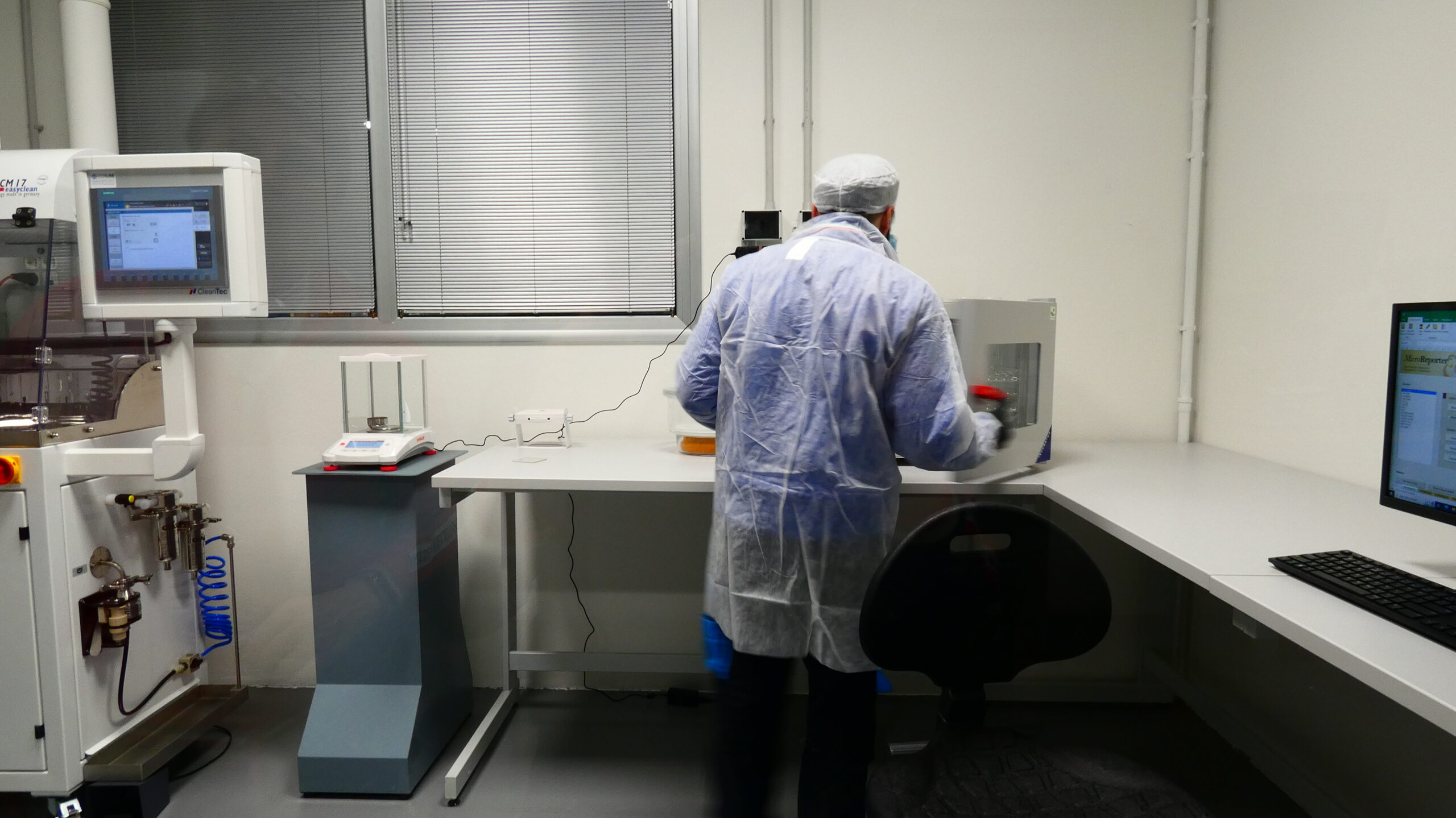

The new cleaning booth was installed in the Omeca laboratories at the Group’s headquarters, in a totally aseptic, controlled environment. The specialized, trained operators who monitor the process have to wear suitable personal protective equipment to ensure a contamination-free environment, totally safe for the technicians themselves.

Once the initial stage of testing and data collection is completed, the plant will be validated and the possibility of implementing it for other product lines will be assessed.

How it works

After the product is loaded into the machine, it is washed. Samples are then collected post-washing for examination. They are subjected to thorough analysis which involves a full gravimetric evaluation to quantify the weight of any contaminants found. This gives a clear overview of the conditions of the product before the manufacturing process is even concluded.

If the results of the analysis fail to meet the specifications, the manufacturing process is halted, and the piece is reworked until the required result is achieved.

It is easy to see the enormous time and cost savings from having this information promptly in a highly complex production process like those found in Cavagna’s factories.