Have you ever thought to yourself…

Is there a ‘way around’ having to replace LPG relief valves?

Well, let’s find out!

Regulations vary all over the World, but no matter where you are, and depending on your local requirements it still takes a lot of time to evacuate a LPG tank (propane container) to replace the external pressure relief valve.

But is there a better, more efficient way?

Well now there is! Cavagna Group has developed, through innovation, the Proxy Valve PV series that can do just that.

Pressure Relief Valves: what are they needed for?

While the LPG pressure relief valve is one of our ‘classics’, the Proxy Valve (PV) version is an adaptation and improvement on it. Actually, this could even be considered a ‘modern classic’ as they have been in circulation in certain countries since 2009.

If you are reading this, you already know your stuff, but we can still start with some basics about relief valves. Alternatively, how about going deeper into the in-depth technical paper about the valves attached here as a PDF.

Pressure Relief Valves are one of the most important parts of the LPG tank equipment. In the unlikely event there is an over pressure build-up, these valves release the excess pressure into the atmosphere.

In a normal operating position, these LPG valves are held closed by the force of a spring. If the pressure in the container increases above the rating of the spring, the pressure relief valve opens to release gas until the pressure falls below the spring rating in which the valve closes.

Smart right?

But as the main title explains, the regulations can make maintenance and managing your equipment, as well as time and resources, a vital part of the process. This is where the Cavagna Group Proxy Valve (PV) series comes in.

Proxy Valve: the Pressure Relief Valves innovation

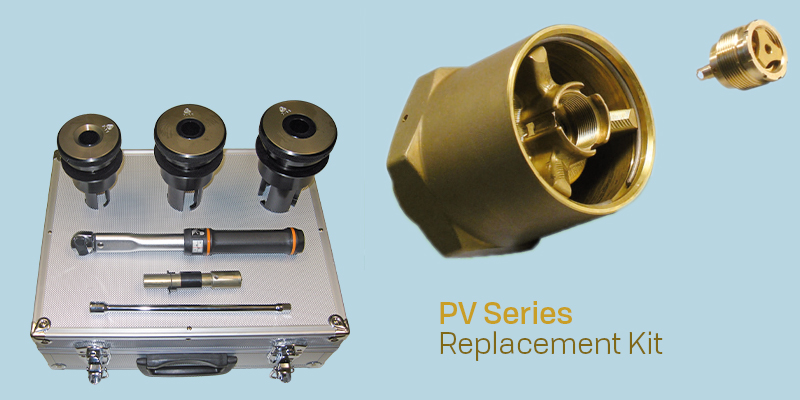

The PV series introduces an important feature, a replaceable cartridge. Thanks to this new component, you no longer have to depressurize the tank to renew your relief valve.

The PV valve has both economic and operational advantages. Its design allows the user to replace the cartridge while the main body of the valve remains installed and the tank remains pressurized therefore eliminating the need to evacuate the tank to replace a traditional pressure relief valve. Moreover, the configuration of the PV Series also reduces the strain on the internal seals compared to ordinary relief valves.

Now users can save time and money by replacing only the cartridge instead of the full valve, which can be done in as little as 5 minutes.

Even smarter right?

Watch the VIDEO here to see how it works.

PV series: benefits

Approved to multiple standards (EN 14129 – EN 14071, UL 132, ASME v8, AFNOR NF: CFBP MA.PV/ST29) the Cavagna Group PV series meets the following 4 demands*.

- SAFE: solves the problem caused by the excessive deformation of the sealing element, made of a rubber compound and assures the closure of the orifice, thus reducing the phenomenon of initial calibration pressure change. Increases the guaranteed stability of parameter settings.

- ECONOMICAL: simplifies operations related to periodic service tests (or periodic calibration) as foreseen by the M.D. 329/04, thus considerably reducing the cost for the carrying out of such interventions, by a replaceable cartridge.

- PRACTICAL: interchangeable with EU series valve and therefore can be mounted on the corresponding check-lock series valve

- ECO-COMPATIBLE: more compact than standard products on the market, means that you can save space where needed.

Understanding the real benefits of the switch is imperative to the overall savings that can be made.

The Cavagna PV series pressure relief valves in conclusion:

- facilitates the operations relevant to the two-year functional inspection foreseen by the M.D. 329/04 and drastically reduces its costs;

- is interchangeable with the EU series valves, therefore it can be fitted to the relevant ST series check-locks;

- increases in time the stability characteristics of the calibration parameters;

- has a lower height with respect to the standard series, which are sold on the market.

*May vary from country to country.

Easy steps for periodical refurbishment of PV Series Pressure Relief Valves

There are significant elements of improvement regarding the operational aspect for the replacement and reduction of LPG dispersion during operation.

A kit is available from Cavagna Group to enable swift and easy changing of the cartridge.

We have more information! By clicking this LINK, you can download the PDF version of the in-depth technical paper here. This will explain the functioning in more detail and if you want to get further information, you can also contact your Cavagna Sales Manager.