With environmental sustainability becoming more and more important, carmakers around the world have projects in the pipeline that aim to increase the use of hydrogen in transport. Interestingly, the industry is no stranger to hydrogen capabilities.

The first hydrogen fuel cell technology actually dates back to 1939.

What has changed since then? First of all, hybrid, plug-in and totally electric vehicles have gradually become an established reality. However, transport powered by conventional batteries presents some critical issues. In particular, it is not an optimal way to power heavy-duty vehicles such as trucks, buses, long-haul vehicles or trains. Indeed, batteries for these kinds of vehicles would be too big and heavy, not to mention the extremely long charging times they would require.

That’s where hydrogen combined with fuel cell technology comes into play. Fuel cells turn the hydrogen on board into electricity, with much higher efficiency and capacity than conventional batteries. Fuel cell vehicles are also more efficient than conventional vehicles with internal combustion engines. Moreover, it is well known that they are pollution free, as they emit only heat and steam.

Hydrogen fuel cell: 5 steps to power motors

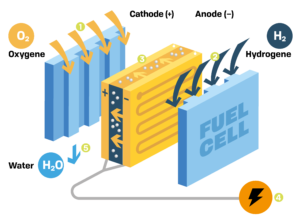

- The oxygen that the fuel cell needs comes directly from outside air.

- Hydrogen is sent to the fuel cell from the tank it’s stored in as a gas.

- The reaction. Hydrogen and oxygen chemically react in the fuel cell and recombine to form water molecules (H20). The reaction generates a flow of electrons.

- The electricity generated in the fuel cell can be fed into the grid or used to power an electric motor (in a car, truck, train, ship, etc.).

- The only by-product of the chemical reaction is water vapor, which is expelled through an exhaust pipe.

Cavagna Group in transport

Nowadays, the demand for hydrogen-powered transport and its market potential is rising. It is therefore we at Cavagna Group have developed a molecular hydrogen valve for fuel cell vehicles. These new hydrogen valves, named HS1, were designed and manufactured by Omeca, our Italian manufacturing unit. Here in Ponte S.Marco (Brescia – ITALY), we also manufacture our line of “Global” valves for CNG containers.

Valves for fuel cell vehicles must have special features if they are to be used for hydrogen storage.

Indeed, H2 gas has extremely small molecules that tend to pass through coating materials, so it is essential to use materials with specific features. Taking into account the particularly high pressure (350-700 bar) at which compressed hydrogen is stored for fuel cell applications, it generates so much force that seals must be tighter. Even the manufacturing process itself requires special measures to be taken. The assembly lines must be set up in a clean room. This prevents contamination of the valves from dirt particles, which could potentially lead to gas leaks.

Do you want to know more about hydrogen? Click HERE.